In the field of outdoor decoration and advertising production, self-adhesive vinyl has won wide market recognition for its unique convenience and durability. However, when these materials face the rigors of the outdoor environment, especially strong sunlight, their UV resistance becomes an important indicator of their quality. This article will take a deep look at the UV resistance of self-adhesive vinyl and how material formulation and production process affect this key performance.

Basic UV resistance of self-adhesive vinyl

As a polymer material, self-adhesive vinyl has a certain UV resistance in its molecular structure. This ability comes from the stability of the chemical bonds inside the material and the natural absorption and scattering of UV rays. However, this basic UV resistance is often limited and difficult to meet the needs of long-term outdoor exposure.

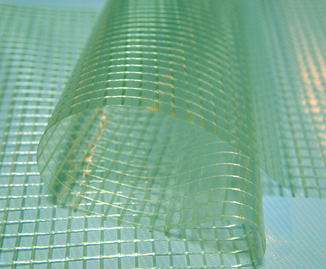

Material formulation: The key to improving UV resistance

To enhance the UV resistance of self-adhesive vinyl, material manufacturers carefully add special UV absorbers or stabilizers to the formula. These additives can absorb or reflect UV rays like "sunscreen" to reduce the direct damage of UV rays to the material. UV absorbers convert UV energy into heat through chemical reactions, while stabilizers protect material molecules from free radical attacks caused by UV rays through physical or chemical effects.

Influence of production process

In addition to material formulation, production process is also one of the key factors that determine the UV resistance of self-adhesive vinyl. Advanced production process can ensure the uniform distribution of additives in the material, avoiding performance differences caused by local concentrations that are too high or too low. At the same time, reasonable processing temperature and pressure control can also effectively reduce the thermal oxidation and photooxidation reactions of the material during processing, further improving its UV resistance.

Challenges under long-term exposure

Although high-quality self-adhesive vinyl uses special UV absorbers and stabilizers and is processed through careful production processes, long-term exposure to strong sunlight may still face challenges. The continuous action of UV radiation will gradually cause the material to fade in color, age on the surface, and deteriorate in performance. Therefore, in outdoor applications, in addition to choosing high-quality self-adhesive vinyl, appropriate sunshade measures and regular maintenance are also required to extend the service life of the material.

The UV resistance of self-adhesive vinyl is an important guarantee for its stability and durability in outdoor environments. By optimizing material formulation and production process, manufacturers can significantly improve the material's UV resistance. However, in the face of long-term and strong sunlight exposure, we still need to remain vigilant and take necessary protective measures to deal with the potential risk of performance degradation. With the continuous advancement and innovation of technology, we have reason to believe that more high-performance self-adhesive vinyl products will be launched in the future, bringing more possibilities to the field of outdoor decoration and advertising production.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126