Industry knowledge

PVC banner material is a popular choice for outdoor advertising due to its durability and versatility. The most common printing methods used for PVC banner material include:

Digital printing: This is the most popular and versatile method of printing on PVC banner material. It involves printing the design directly onto the material using a large format digital printer. Digital printing is capable of producing high-quality images and can handle complex designs with multiple colors.

Screen printing: This method involves pressing ink through a stencil onto the PVC banner material. It is typically used for large print runs and produces vibrant colors that are long-lasting.

Offset printing: This method involves transferring ink onto a rubber blanket before transferring it to the PVC banner material. It is best suited for high-volume print runs and produces sharp, detailed images.

UV printing: This method uses ultraviolet light to cure the ink as it is printed onto the PVC banner material. UV printing produces high-quality images and is particularly effective for printing on dark-colored PVC banner material.

The choice of printing method will depend on various factors, including the design, quantity, and budget. Digital printing is the most common method used for PVC banner material due to its versatility, speed, and cost-effectiveness. However, screen printing and offset printing may be more suitable for large print runs or designs that require specific color matching. UV printing is ideal for printing on dark-colored PVC banner material or when durability is a top priority.

What are the proper storage and handling techniques for PVC banner material?

Proper storage and handling of

PVC banner material are crucial to ensure the material remains in good condition and maintains its quality. Here are some tips for storing and handling PVC banner material:

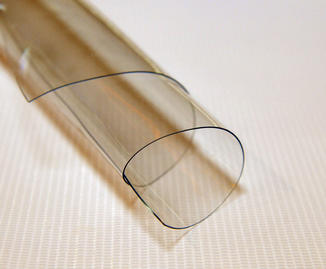

Store the PVC banner material in a cool, dry place, away from direct sunlight, moisture, and heat sources. PVC banner material should be stored in a vertical position to prevent it from bending or folding.

If the PVC banner material is rolled, make sure to roll it with the printed side facing outward to prevent creasing or damage to the printed surface.

Avoid storing PVC banner material near chemicals, solvents, or other materials that may cause damage or discoloration.

When handling PVC banner material, avoid touching the printed surface as much as possible. Wear clean gloves to prevent dirt, oil, or other contaminants from transferring onto the material.

When transporting

PVC banner material, make sure to package it securely to prevent it from being damaged during transit. Use a protective sleeve or packaging material to prevent it from rubbing against other materials or surfaces.

If the PVC banner material becomes wrinkled or creased, gently stretch it out or use a heat gun to remove the wrinkles.

Always follow the manufacturer's instructions for cleaning and maintaining PVC banner material. Use mild soap and water to clean the material, and avoid using harsh chemicals or abrasive materials that may damage the printed surface.