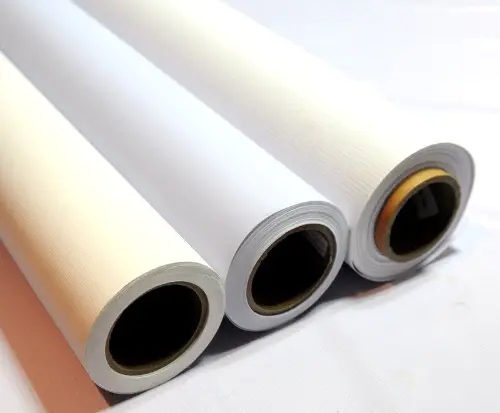

The outdoor advertising industry is ushering in a major breakthrough in material technology - the new generation of PVC Banner has redefined the durability standards of outdoor advertising with its excellent tear resistance and fading resistance. This technology upgrade not only extends the service life of advertising materials, but also significantly reduces maintenance costs, providing advertisers and producers with more competitive solutions.

Tear resistance technology: from material structure to weaving process

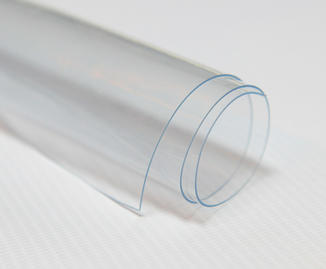

Traditional PVC Banners are prone to tearing problems under strong winds or external forces, resulting in damage to the advertising screen and affecting the promotional effect. The latest developed high-strength PVC composites have achieved breakthrough improvements through the following technologies:

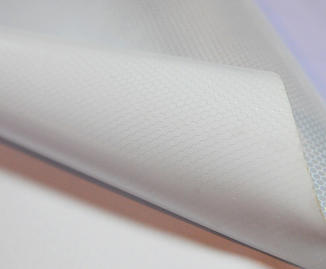

1. Multi-layer composite structure: The high-density polyester fiber base fabric and PVC coating composite process is adopted to significantly improve the tensile strength of the material and can withstand greater wind pressure and physical impact.

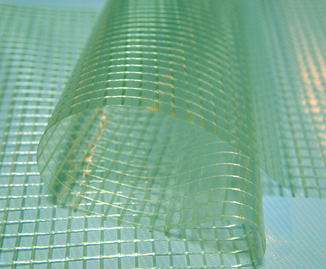

2. Cross-weaving technology: Optimize the fiber weaving angle so that the material can evenly disperse the pressure when under stress, and reduce the risk of tearing caused by stress concentration.

3. Edge reinforcement treatment: Through hot melt edge sealing or high-frequency welding technology, the stability of the banner edge is enhanced to avoid common edge cracking problems.

Breakthrough in anti-UV and anti-fading technology

Outdoor advertising has long been exposed to sunlight and rainy environments, and color attenuation has always been a pain point in the industry. The latest technology solves this problem from multiple levels:

1. Advanced UV stabilizer: Adding a new light stabilizer to the PVC formula can effectively absorb ultraviolet rays and convert them into harmless thermal energy, greatly delaying the aging process of materials.

2. Nano-scale pigment protection: Use microcapsule wrapping technology to protect ink molecules to prevent ultraviolet rays from directly destroying the color structure, so that the picture remains brighter and lasting.

3. Surface self-cleaning coating: Some high-end products have added hydrophobic coatings to reduce dust adhesion and rainwater erosion, while reducing the frequency of cleaning and maintenance.

Environmental protection and sustainability innovation

As global environmental regulations become stricter, the PVC Banner industry is also actively promoting green transformation:

1. Heavy metal-free formula: eliminate traditional stabilizers containing lead and cadmium, adopt environmentally friendly alternatives such as calcium and zinc, and comply with RoHS and REACH standards.

2. Recyclable design: improve the singleness of material components and improve recycling rate. Some manufacturers have established closed-loop recycling systems.

3. Bio-based plasticizers: The new generation of products under development try to use plant-derived plasticizers to further reduce the environmental footprint.

Market applications and future trends

The PVC Banner after the technology upgrade has shown its advantages in many fields:

1. Long-term outdoor advertising: Highway billboards, building fences and other scenarios that require durability benefit significantly.

2. Event exhibition: Even if it is reused many times, it can still maintain a good visual effect.

3. Extreme climate areas: It is particularly prominent in areas with high temperature, high ultraviolet rays or strong winds.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126