As industrial materials increasingly pursue functionality and reliability, medium- and heavy-duty PVC coated tarpaulin fabric are finding widespread use in a variety of specialized applications thanks to their mechanical properties and stable environmental adaptability. This new generation of PVC tarpaulins, combining a high-density base fabric, a polymer coating process, and a finely woven structure, not only meets everyday coverage needs but also demonstrates strong potential in high-end equipment protection and temporary structure construction.

High-strength protective performance stems from upgraded material structure

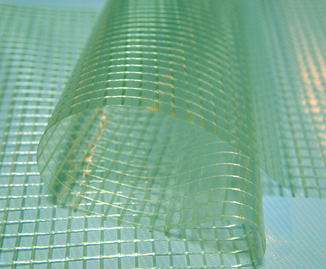

PVC-coated tarpaulin fabric, also known as PVC coated tarpaulin fabric, is a composite material made from a high-strength polyester fiber base fabric coated on both sides with polyvinyl chloride. Compared to traditional materials like canvas and PE tarpaulins, PVC coated tarpaulin fabric offers significant advantages in terms of water resistance, sealing, and aging resistance. Heavy-duty PVC-coated fabrics, in particular, undergo a dual galvanizing and powder coating process, enhancing their stability and corrosion resistance in weather conditions. Furthermore, heat-sealed seams ensure seamless protection, effectively preventing water penetration and crack propagation. PVC tarpaulins maintain tensile strength in strong winds, resisting tearing or structural failure even in sustained winds exceeding 140 mph. They are suitable for conditions such as covering high-altitude equipment and prolonged outdoor exposure.

Diverse Applications: From Truck Side Covers to Inflatable Structures

With its stable physical properties and flexible production capabilities, PVC coated tarpaulin fabric serve a wide range of industries:

Transportation and Warehousing: Used as truck tarpaulins, freight side covers, and logistics enclosures, they provide rain and dust protection, safeguarding cargo integrity.

Construction and Engineering: Used for temporary fencing, construction site shelters, and rainproofing building structures.

Sports and Leisure: Widely used in inflatable toys, amusement rides, and outdoor awnings.

Lifestyle and Decoration: Used as curtains, door curtains, and canopies, offering durability and rich colors.

Emergency Applications: Used in disaster relief for simple tents, storage facilities, and protective covers.

This versatile adaptability has led PVC tarpaulins to gradually replace traditional PE fabrics and canvas, becoming the standard choice for multi-purpose protective applications.

Flexible Specifications: Highly Customizable to Meet Various Scenario Needs

Unlike pre-made fabrics, PVC-coated tarpaulins offer a high degree of customization. From weight, width, length, to color, any combination can be tailored to your needs, ensuring both efficiency and aesthetics.

|

Parameter Category |

Optional Range/Description |

|

Thickness |

0.19mm - 2.0mm (Medium to Heavy Duty) |

|

Weight |

340g/㎡ - 1500g/㎡ (Customizable) |

|

Width |

1.02m - 3.20m |

|

Length |

50m - 100m per roll |

|

Material Composition |

70% PVC coating + high-strength polyester base fabric |

|

Weave Density |

18×18, 20×20, 23×23, 25×25, 30×30 |

|

Yarn Gauge |

840D, 1000D, 1300D |

|

Surface Treatment |

Glossy / Matte |

|

Coating Type |

Single/Double-Sided PVC Coating |

|

Color Options |

Champagne, Gray, Green, Khaki, Light Blue, etc. |

Process Advantages: Heat-Sealed Seams and Eco-Friendly Packaging

In terms of production, heavy-duty PVC waterproof fabrics utilize heat-sealed seams to create seamless connections, preventing leaks and structural vulnerabilities. Products are typically packaged in kraft paper or rigid tubes, facilitating transportation and storage while effectively protecting the fabric surface from damage. Furthermore, in response to the green development trend, some manufacturers are exploring renewable formulas and eco-friendly additives, driving the development of PVC materials towards low-VOC and recyclable properties.

Conclusion: PVC Tarpaulins Will Become Smarter and Greener in the Future

PVC tarpaulins are no longer simply rainproof materials; they are now professional protective solutions that combine durability, safety, and aesthetics. Their widespread application represents a new understanding of material performance, environmental adaptability, and aesthetic value. As industry demands become increasingly diverse, future PVC-coated tarpaulins will continue to evolve in terms of intelligent weaving, integrated functionalities (such as flame retardancy, anti-static properties, and infrared reflectivity), and environmentally friendly manufacturing. For customers seeking reliability, efficiency, and long-term value, choosing a high-quality, customized PVC tarpaulin means building a protective barrier that balances safety and efficiency.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126