In the field of advertising and display solutions, flex banner material has maintained a strong presence due to its versatility and adaptability for printing. With the rapid growth of outdoor advertising, exhibitions, and public promotions, the feature that continues to draw the attention is weather resistance. From withstanding harsh sunlight to enduring rainfall and temperature fluctuations, the weather resistance of flex banner material has become a decisive factor in measuring its long-term value.

Weather Resistance as a Core Attribute

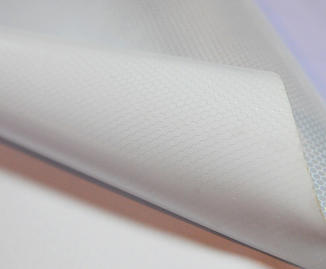

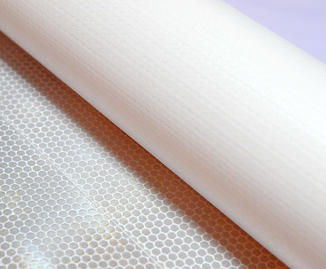

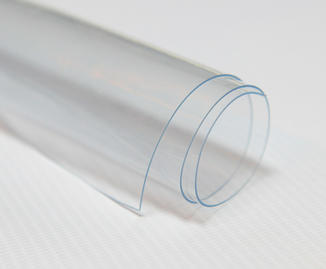

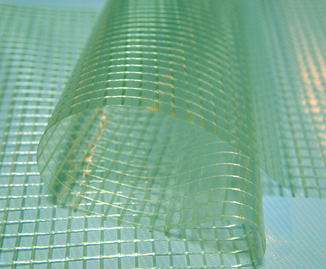

Structurally, flex banner material is commonly composed of PVC layers combined with polyester fabric, providing durability and flexibility. However, when applied in outdoor advertising or long-term displays, its lifespan and reliability are defined primarily by weather resistance. This feature includes the ability to resist ultraviolet radiation, protect against moisture, and adapt to wide temperature ranges.

The market has increasingly turned to eco solvent flex banner and uv resistant flex banner material in response to growing environmental awareness. Weather resistance has thus evolved from a technical characteristic into a broader indicator of application value, environmental sustainability, and overall product lifecycle.

Connection Between Weather Resistance and Print Quality

For flex printing material, one of the important aspects is the ability to reproduce vibrant graphics with high resolution. Without sufficient weather resistance, outdoor prints risk fading, distortion, and diminished visual impact over time. Weather resistance, therefore, is not merely structural durability—it is a direct factor in ensuring effective advertising communication.

This correlation between durability and quality has shaped the development of products such as printable flex banner, frontlit flex banner, and backlit flex banner. Each variant is designed to serve specific conditions, with weather resistance determining how well they perform across environments.

Key Indicators of Weather Resistance

The weather resistance of flex banner material is typically assessed through measurable indicators. These indicators provide benchmarks for comparing different product types and applications.

| Indicator Category | Description | Typical Application |

|---|---|---|

| UV Resistance | Ability to retain color stability and reduce fading under sunlight | uv resistant flex banner material |

| Waterproofing | Resistance to deformation under rain or high humidity | waterproof pvc flex banner material |

| Temperature Range | Flexibility retention in high or low temperatures | outdoor flex banner roll |

| Service Life | Stability of structure over extended periods of use | high quality flex banner for signage |

Variations in Application Requirements

Different applications demand varying levels of weather resistance from flex banner material. For outdoor billboards, waterproofing and UV resistance are primary considerations. In exhibition displays, flexibility and precise print retention are often more critical.

Frontlit pvc flex banner material is widely used in storefronts and event backdrops, while backlit flex banner material serves effectively in illuminated displays and lightboxes. Meanwhile, flex banner material for digital printing must not only absorb ink effectively but also maintain color consistency under challenging conditions. Custom size printable flex banner sheet has also emerged to meet tailored project requirements.

Market Demand Driven by Weather Resistance

As businesses prioritize higher-quality advertising displays, weather resistance has become a central factor in procurement decisions. Buyers of waterproof pvc flex banner material or high quality flex banner roll are no longer focused solely on cost but also on long-term stability in outdoor use.

This shift in demand is reflected in increased interest in bulk orders and customization. Keywords such as cheap wholesale flex banner material online and flex banner material supplier highlight the balance between affordability and durability sought by the market.

Weather Resistance in Industry Standards

From an industry perspective, weather resistance is increasingly being integrated into standardized product performance metrics. Categories like uv resistant flex banner material and eco-friendly flex banner material for printing represent a structured approach to addressing diverse usage environments.

Standardization is also seen in specifications for flex banner roll and flex banner sheet, where parameters like thickness, durability, and resistance are being refined. This transparency allows buyers and users to make informed decisions, further reinforcing weather resistance as an essential product benchmark.

Future Directions of Weather Resistance

Eco-Resistant Development: Adoption of recyclable or low-emission pvc flex banner solutions that extend lifespan while reducing environmental impact.

Digital Printing Compatibility: Advancements in flex banner material for digital printing will combine vivid image reproduction with enhanced weather resistance.

Multi-Scenario Adaptability: From frontlit flex banner to backlit flex banner, products will increasingly be engineered to function across diverse environmental and commercial conditions.

Weather resistance is no longer a secondary characteristic but the defining feature of flex banner material. From UV protection to waterproof durability, from thermal adaptability to long-term stability, weather resistance shapes how the material performs in real-world applications.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126