In the global materials market, the emphasis on durability has become a decisive factor in industrial and commercial applications. Among the wide range of materials, PVC laminated tarpaulin fabric has emerged as a key solution, offering a unique combination of strength, flexibility, and resilience. The material’s robust construction and versatile applications have positioned it as a cornerstone for outdoor coverings, industrial shelters, and protective solutions.

Rising Importance of Durable Materials

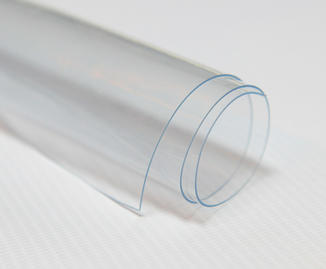

Durability is no longer a secondary consideration in material selection. For industries ranging from construction to logistics, the ability of a material to withstand environmental stress, mechanical wear, and prolonged exposure to sunlight or moisture is critical. PVC laminated tarpaulin fabric, designed with a laminated PVC coating, ensures resistance to tearing, abrasion, and weathering, making it an ideal choice for heavy-duty industrial use. Its waterproof properties enhance its functionality in both temporary and permanent structures, ensuring protection in adverse conditions.

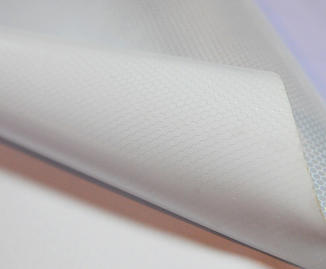

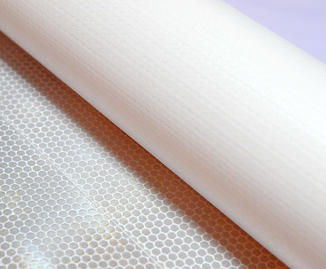

Material Structure and Durability

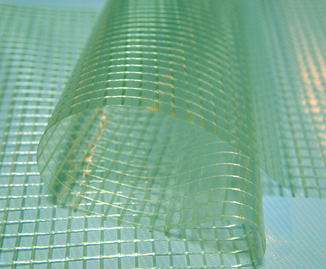

The durability of PVC laminated tarpaulin fabric lies in its unique structure. A core base fabric, typically polyester or other high-strength fibers, is coated with multiple layers of PVC lamination. This combination not only reinforces the fabric but also provides enhanced tear resistance and UV protection. Unlike conventional fabrics, which may degrade or lose structural integrity over time, laminated PVC sheets maintain their performance across varying environmental conditions. The incorporation of high-quality PVC ensures that the material remains resistant to corrosion, mold, and chemical exposure, extending its service life significantly.

Applications Emphasizing Longevity

One of the primary drivers of the increasing adoption of PVC laminated tarpaulin fabric is its suitability for applications where long-term durability is essential. In logistics, it serves as truck covers that protect goods from rain, dust, and mechanical stress. In construction, it functions as scaffolding covers or temporary shelters, enduring exposure to wind and sunlight without compromising integrity. Outdoor recreational equipment, such as tents and awnings, also benefits from its weatherproof and tear-resistant properties. By addressing multiple performance requirements simultaneously, the material reduces maintenance costs and replacement frequency, enhancing operational efficiency.

Environmental and Performance Advantages

Modern developments in PVC laminated tarpaulin fabric production emphasize not only mechanical durability but also environmental and safety considerations. Flame retardant properties, eco-friendly formulations, and non-toxic coatings ensure compliance with industry standards while maintaining high performance. Weatherproof and UV-resistant variants extend the usability of tarpaulin sheets in outdoor conditions, providing reliable protection for extended periods. Additionally, the flexibility and lightweight nature of the material simplify installation and handling without compromising its strength.

Industry Trends and Innovation

The market for PVC laminated tarpaulin fabric is being shaped by increasing demand for materials that combine durability with multi-functionality. Manufacturers are focusing on enhancing resistance to environmental factors, optimizing lamination techniques, and developing specialized coatings to improve longevity. Innovations in anti-aging treatments and abrasion resistance are expanding the applicability of tarpaulin fabrics in more demanding industrial contexts. These developments align with the broader trend of industrial materials prioritizing lifecycle performance, cost-effectiveness, and operational reliability.

Versatility as a Competitive Edge

Another key aspect of durable PVC laminated tarpaulin fabric is its versatility. The material is not limited to industrial use; it extends to agricultural applications, where it functions as greenhouse covers or protective sheets for crops. In marine environments, laminated PVC fabric serves as boat covers and dock protection, demonstrating resilience against saltwater corrosion. The combination of high-strength fabric and laminated PVC coating ensures that the material adapts to a wide array of applications while consistently delivering reliable performance.

The growing reliance on PVC laminated tarpaulin fabric underscores the critical role of durability in material selection. Its combination of strength, weather resistance, flexibility, and longevity addresses the evolving demands of industrial, commercial, and outdoor applications. As innovation continues to enhance its performance, the material is expected to become an increasingly preferred choice across sectors that require dependable, long-lasting protective solutions. By emphasizing durability as a core feature, PVC laminated tarpaulin fabric sets a benchmark for industrial fabrics, reinforcing the importance of robust and reliable materials in a fast-paced and demanding market.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126