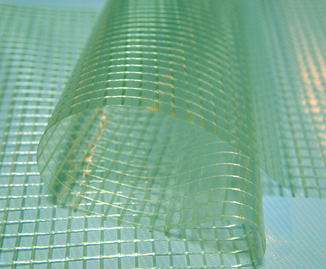

Market Overview of PVC Coated Tarpaulin Fabric

PVC coated tarpaulin fabric has established itself as a critical material in industrial, agricultural, and outdoor applications due to its remarkable durability and functional versatility. Its inherent characteristics, particularly its waterproof capability, make it indispensable for protective coverings, truck tarps, tents, and temporary shelters. The global demand for PVC coated tarpaulin fabric has seen a consistent increase as industries emphasize durability, weather resistance, and cost efficiency.

Several factors contribute to the growth of this market. Rising infrastructural development projects, expanding outdoor recreational activities, and the need for reliable storage and transport solutions have significantly increased the adoption of PVC coated tarpaulin fabric. Additionally, the material’s versatility allows for customization, including UV resistance, fire retardancy, and anti-mildew properties, which cater to diverse industry requirements.

Technical Features of PVC Coated Tarpaulin Fabric

The technical excellence of PVC coated tarpaulin fabric is primarily rooted in its unique structure, which combines a polyester base with a high-quality PVC coating. This composite construction ensures enhanced tensile strength, dimensional stability, and resistance to environmental stressors. Among its notable features are:

- Waterproofing: Ensures complete protection against rain and moisture.

- UV Resistance: Extends product longevity under prolonged sun exposure.

- Fire Retardancy: Provides safety in industrial and commercial applications.

- Tear and Abrasion Resistance: Critical for heavy-duty industrial usage.

- Flexible Handling: Allows easy installation in temporary or permanent setups.

In-depth Analysis of Waterproof Performance

Among the technical attributes, the waterproof performance of PVC coated tarpaulin fabric is paramount. This feature is the cornerstone of its application in outdoor and industrial settings. The PVC coating forms a continuous layer that prevents water penetration, while the polyester base provides structural integrity. This combination ensures that the fabric can withstand both static water accumulation and heavy rainfall over extended periods.

Waterproof Performance Comparison Table

| Feature | Description | Benefit to End-user |

|---|---|---|

| Coating Thickness | 0.3–0.5 mm PVC layer | Prevents water seepage, enhances durability |

| Water Column Rating | 5000–7000 mm water resistance | Assures reliability in heavy rain conditions |

| Seam Sealing Techniques | Heat-welded or high-frequency welded seams | Eliminates leakage through joints |

| Surface Treatment | Anti-mildew and UV resistant coatings | Maintains waterproofing while resisting degradation |

| Tensile Strength | 800–1200 N/5cm | Supports structural load without water penetration |

The waterproof feature also directly impacts product usability across sectors. In agricultural settings, PVC coated tarpaulin fabric is used to protect crops, livestock, and equipment. In the transportation sector, it safeguards goods against moisture during transit. For outdoor events, it provides a reliable barrier against unpredictable weather.

Application Scenarios of PVC Coated Tarpaulin Fabric

The multifunctionality of PVC coated tarpaulin fabric is largely derived from its waterproof performance. Key application areas include:

- Industrial Covers: Machinery, equipment, and storage facilities require waterproof protection to prevent corrosion and operational downtime.

- Agriculture: Livestock shelters, crop protection, and irrigation covers benefit from durable, water-resistant fabric.

- Transportation: Truck tarps and shipping covers rely on waterproof PVC tarpaulin fabric to ensure cargo safety.

- Outdoor Recreational Uses: Tents, canopies, and event shelters leverage the fabric’s waterproof and UV-resistant properties.

Production and Quality Control

High-quality PVC coated tarpaulin fabric production involves rigorous quality control processes to ensure waterproof performance. Key steps include:

- Raw Material Selection: Premium polyester base combined with high-grade PVC coating.

- Coating Application: Uniform application techniques for consistent waterproofing.

- Seam and Edge Treatment: Ensures long-term durability and leak prevention.

- Laboratory Testing: Water column tests, UV resistance assessments, and abrasion resistance evaluations.

- Packaging and Storage: Prevents damage and maintains functional integrity during transport and storage.

Future Trends in PVC Coated Tarpaulin Fabric

As industries and consumers increasingly demand sustainable and high-performance materials, the PVC coated tarpaulin fabric sector is evolving. Innovations include lighter yet stronger fabrics, improved eco-friendly PVC formulations, and enhanced multifunctional coatings that provide additional resistance to UV, chemicals, and mechanical wear. These advancements will continue to drive global adoption and maintain the relevance of PVC coated tarpaulin fabric in diverse applications.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126