Anti-aging technology promotes the performance of PVC tarp

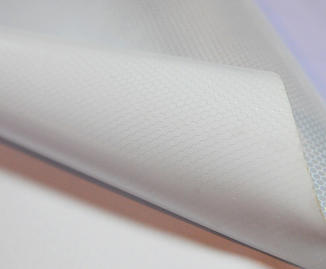

Traditional PVC tarpaulin is prone to problems such as embrittlement, fading and decreasing strength when exposed to ultraviolet rays, extreme temperatures and chemically corroded environments for a long time. The latest generation of anti-aging PVC tarp effectively solves these pain points through multiple technological innovations. Materials scientists have added specially formulated UV absorbers and light stabilizers to PVC substrates. These additives can effectively block harmful UV radiation and significantly delay the material's photooxidation process.

In addition to UV protection, the modern PVC tarp also uses advanced antioxidant formula. The stabilizers in these formulations are able to neutralize free radicals and prevent breakage of polymer chains, thereby maintaining the flexibility and mechanical strength of the material. Under extreme temperature environments, the modified PVC composites exhibit more stable performance, maintaining excellent physical properties in severe cold and hot summers. This all-round anti-aging protection allows the service life of PVC tarpaulin to be 2-3 times longer than that of traditional products.

Multi-dimensional improvement of industrial-grade protective performance

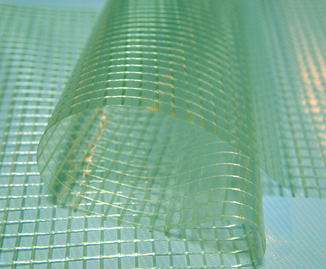

The requirements for protective materials in modern industry are no longer limited to basic waterproofing functions. High-end PVC tarp now has more comprehensive protection features and can meet various rigorous industrial application scenarios. In terms of chemical corrosion resistance, the new formula can resist the corrosion of a variety of industrial chemicals, oil pollution and solvents, and is especially suitable for applications in chemicals, minerals and other fields.

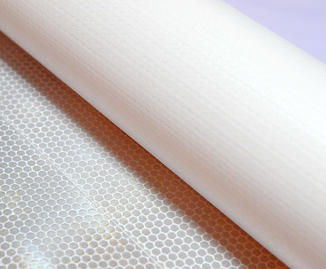

Improvement of mechanical performance is another important breakthrough. By optimizing the braiding process and coating technology, the current PVC tarpaulin has higher tear strength and wear resistance. Some high-end products can even meet military-level protection standards and can withstand the test of extreme weather conditions such as strong winds and hail. Fire resistance has also been significantly improved. The application of flame retardant formulas allows the materials to self-extinguish when encountering open flames, greatly improving the industrial safety level.

Breathability balance is another highlight of technological innovation. The new generation of PVC tarp cloth achieves a perfect combination of waterproofing and breathable through microporous technology. This feature shows unique advantages in warehousing, agriculture and other applications that require moisture resistance and ventilation. The development of intelligent temperature-controlled coatings is further developed, which can automatically adjust surface characteristics according to the ambient temperature, reflect heat in hot environments, and maintain internal temperature under cold conditions.

Sustainable manufacturing promotes green development in the industry

With the increasing strict environmental regulations and the popularization of sustainable development concepts, PVC tarpaulin manufacturing industry is also actively transforming. The latest production processes significantly reduce energy consumption and waste generation, and many manufacturers have implemented closed-loop water circulation systems for the production process. In terms of materials, the use of heavy metal stabilizers and environmentally friendly plasticizers makes the product safer and more reliable.

Recyclability has become the new industry standard. The modern PVC tarp has considered the end-of-life treatment solution in the design stage. Through material purification and special recycling processes, waste tarp can be efficiently recycled and reused. Some leading companies have also developed bio-based PVC alternative materials to further reduce the product's carbon footprint. These environmental innovations not only respond to global sustainable development initiatives, but also provide end users with more ESG-compliant procurement options.

Intelligent applications open a new era of industrial protection

Technological innovation is promoting the development of PVC tarpaulin towards intelligence. Smart tarps with integrated sensing technology can monitor environmental parameters and material status in real time, providing early warning and data analysis through the IoT platform. This intelligent feature is of great value in scenarios such as monitoring of large industrial facilities and storage of dangerous goods.

The application of self-healing materials is another breakthrough. When there is slight damage to the surface of the PVC tarp, the specially formulated coating can be automatically repaired to maintain protective performance. The introduction of photocatalytic self-cleaning technology greatly reduces maintenance costs, and the surface of the material can decompose organic pollutants under sunlight and maintain a clean state. These intelligent features are redefining the standards and possibilities of industrial protection.

In the future, with the integration and application of cutting-edge technologies such as nanotechnology and new composite materials, the performance boundaries of PVC tarp will continue to expand. From polar investigation to desert operations, from maritime platforms to space exploration, anti-aging PVC tarpaulin is providing increasingly reliable protection for human activities in extreme environments, and its industrial application prospects are limitless.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126