UV printing technology improves weather resistance of PVC banners

Traditional solvent-based or Latex inks are prone to degradation due to ultraviolet rays in outdoor environments, causing the color of PVC banner to gradually fade and even the material to brittle. UV printing uses light-curing ink, which instantly cures under the irradiation of UV-LED lamps, forming a solid protective film. This curing process not only improves the adhesion of the ink, but also enhances the resistance to ultraviolet (UV) and allows the PVC banner to maintain bright colors during long-term outdoor use.

UV ink itself has excellent weather resistance, can withstand UVA and UVB radiation in sunlight, reducing the damage to the material by the photooxidation reaction. In addition, the ink layer of UV printing has certain waterproof and chemical corrosion resistance, which can effectively resist the erosion of rainwater, moisture and air pollutants, thereby extending the service life of PVC banner.

UV printing can also further enhance the anti-aging ability of PVC banner by adjusting the ink formula and adding special weathering aids such as light stabilizers and antioxidants. These additives can absorb or scatter UV rays, slowing down the aging process of materials and ensuring that the advertising image remains clear and bright in the outdoor environment for a long time.

How to optimize the color expression of PVC banners in UV printing

Color expressiveness is one of the important indicators for measuring the quality of PVC banner. UV printing technology can present richer and more saturated color effects with its high-precision inkjet system and wide color gamut ink. Compared with traditional printing methods, UV printing has a wider color gamut, covering more than 90% of the Pantone color card, ensuring that the color levels of the advertising screen are more delicate and the gradient transition is more natural.

The high color concentration properties of UV ink allow it to form a thicker ink layer on the PVC banner, thereby enhancing the hiding power and three-dimensionality of the color. Whether it is high-contrast text or complex image details, UV printing can accurately restore it to avoid color deviation or smudge. In addition, UV printing supports white ink and varnish coatings, allowing for brighter patterns on dark backgrounds or adding gloss to specific areas, enhancing overall visual appeal.

The instant curing properties of UV printing also reduce the risk of ink diffusion, ensuring sharp edges of color and avoiding blur or bleaching problems. This is especially important for advertising designs that require fine lines and high-resolution images, such as brand LOGOs, QR codes or HD photos.

Coordinated optimization of UV printing and PVC banner materials

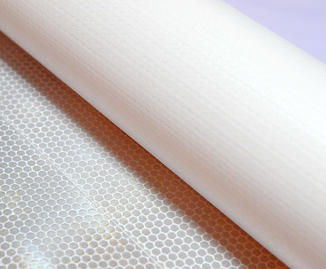

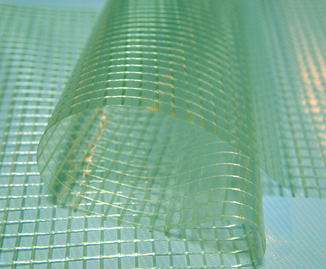

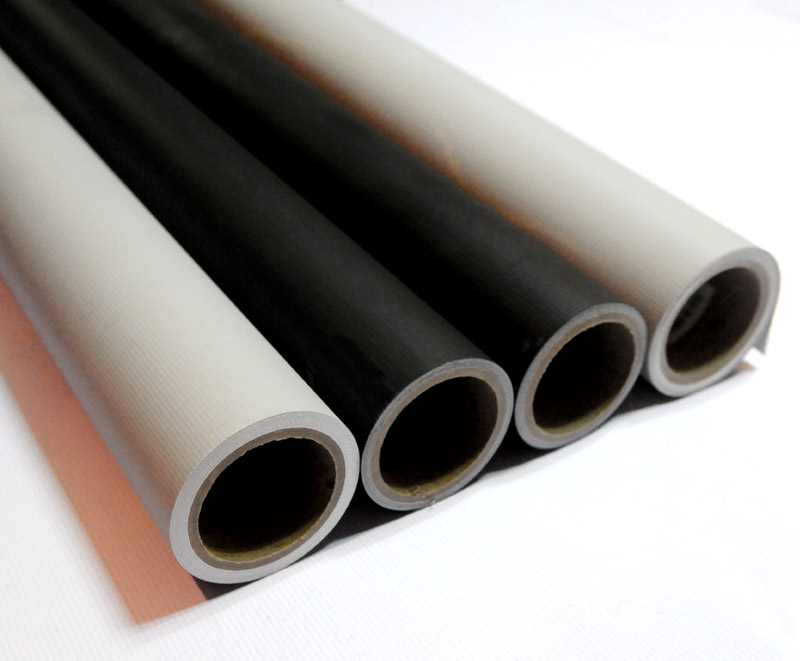

PVC banner's performance depends not only on the printing technology, but also closely related to the quality of the substrate. The high-quality PVC material itself has good flexibility and tear resistance. Combined with UV printing technology, it can further improve the overall durability. The bonding force between UV ink and PVC substrate is extremely strong, and it is not easy to fall off or crack after curing. Even under strong winds or frequent curling, it can maintain a stable printing effect.

To maximize the advantages of UV printing, many manufacturers use double-sided coated PVC banner materials to enhance UV and scratch resistance. Some high-end PVC banners will also add a protective film to the surface to further improve weather resistance and pollution resistance, and are suitable for long-term outdoor display.

In addition, the environmentally friendly characteristics of UV printing have also made it the mainstream choice for advertising printing in the future. Compared with solvent-based inks, UV inks do not contain volatile organic compounds (VOCs), reducing environmental pollution and improving the safety of the working environment.

Future Trends: The Development of UV Printing and Smart PVC Banners

With the advancement of digital printing technology, the application of UV printing in the PVC banner field will be further expanded. Future development trends may include:

- Application of smart ink: Temperature-changing or light-changing ink can change colors according to ambient light or temperature, enhancing the interactive and attractiveness of advertisements.

- Longer weather resistance: Through nanocoating technology, the resistance to UV, pollution and self-cleaning capabilities can be further improved, so that PVC banner can still maintain excellent performance in extreme climates.

- The combination of sustainable materials: Use recyclable PVC or bio-based materials, combined with UV printing technology to promote the development of environmentally friendly advertising solutions.

UV printing technology enables PVC banner to occupy a more important position in the outdoor advertising market by improving weather resistance and color expression. With the continuous innovation of technology, UV printing will continue to promote the performance upgrade of advertising materials to meet the brand’s needs for high-quality and long-life advertising display.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126