Selecting the right PVC banner material is a critical decision that directly affects printing quality, durability, installation efficiency, and the overall performance of visual communications. As outdoor and indoor advertising formats continue to diversify, choosing a material that meets technical, environmental, and aesthetic requirements becomes essential for producing stable and long-lasting large format printing results.

Why Material Selection Matters in Banner Printing

PVC banner material plays a foundational role in modern outdoor banner printing and promotional displays. Its structural stability, print adaptability, and weather resistance make it suitable for a wide range of environments such as building façades, retail fronts, roadside advertising, event backdrops, trade show displays, and indoor signage applications.

Proper selection ensures:

- Stable and high-resolution printing results

- Improved UV resistance and color retention

- Enhanced mechanical strength in wind, rain, and temperature changes

- Smooth installation and reduced risk of curling or tearing

- Cost-effective long-term usage

The selection process requires a technical understanding of material construction and the relationship between printing methods and banner substrates.

Understanding the Construction of PVC Banner Material

Different performance characteristics originate from the base fabric, coating technology, and surface treatments. A well-constructed PVC banner material delivers strength while maintaining flexibility for various installation methods.

Core Material Components

PVC banner material consists mainly of:

- A reinforced base fabric (often polyester mesh or scrim)

- PVC coating layers

- Additional finishing layers depending on application needs

Key Structural Types

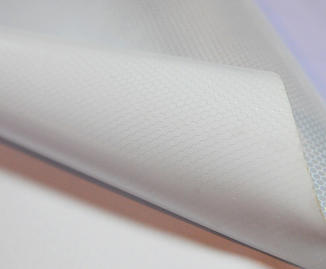

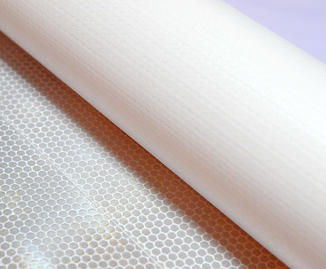

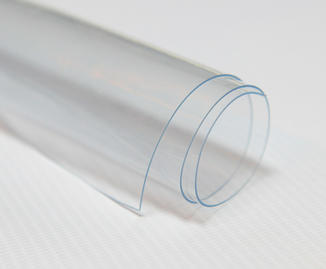

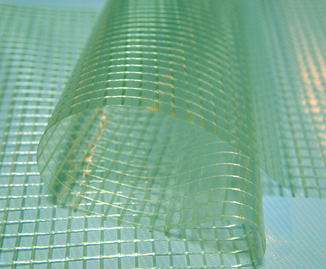

The three main categories include laminated, coated, and mesh PVC banner material.

| Material Type | Structural Features | Typical Characteristics | Common Applications |

|---|---|---|---|

| Laminated PVC banner | PVC films laminated to a polyester scrim | Lightweight, economical, suitable for mid-term use | Indoor signage, promotional banners |

| Coated PVC banner | Liquid PVC coated onto base fabric during production | Stronger, smoother, high durability | Outdoor banners, large format printing, long-term displays |

| Mesh PVC banner | Perforated surface with airflow design | Wind-resistant, reduces pressure on installations | Building wraps, scaffolding banners, large outdoor displays |

Understanding these structures helps align material performance with specific project requirements.

Evaluating Surface Finish and Print Compatibility

Surface texture determines ink adhesion, color performance, and final visual effect. Selecting the correct finish can improve clarity, vibrancy, and viewing comfort.

Glossy vs. Matte Surfaces

Different lighting environments require different optical effects.

-

Glossy finish

Enhances color depth and saturation, suitable for small indoor displays and high-impact visuals. -

Matte finish

Eliminates glare and reflection, ideal for outdoor banner printing and large displays.

Smoothness and Ink Absorption

High-quality PVC banner material should provide:

- Consistent ink absorption

- Smooth print surface

- Reduced dot gain in high-resolution printing

This ensures compatibility with solvent, eco-solvent, UV, and latex inks widely used in large format printing.

Durability Factors That Influence Material Selection

Not all environments present the same challenges. Long-term outdoor use requires improved mechanical properties and environmental resistance.

Weather Resistance

Weather-resistant banner materials should maintain performance in:

- UV exposure

- Rain and humidity

- Extreme temperatures

- Wind load conditions

These environmental variables directly affect banner longevity.

Strength and Tear Resistance

Base fabric density and PVC coating thickness affect:

- Tensile strength

- Tear resistance

- Flexibility under pressure

These properties are essential for banners installed in open or high-wind environments.

Fire Resistance and Safety

Some projects require fire-retardant materials to comply with indoor installation standards such as shopping malls, exhibition halls, airports, and public facilities.

Matching PVC Banner Material to Real-World Applications

Identifying the intended application is the fastest way to narrow material choices. Each scenario demands distinct performance characteristics.

Indoor Promotional Displays

Indoor applications prioritize visual quality over durability. Suitable features include:

- Laminated structure

- Lightweight material

- Smooth, matte or glossy options

- High color performance

Outdoor Advertising and Large Format Printing

Outdoor environments require:

- High tensile strength

- Enhanced UV resistance

- Thick coating layers

- Windproof or mesh structures for large installations

Outdoor banner printing benefits from coated PVC materials due to their stability and long-term performance.

Event Backdrops and Stage Decorations

These banners must balance:

- Portability

- High print quality

- Repeated installation capability

Flexible coated materials are commonly preferred.

Building Wraps and High-Wind Installations

Mesh PVC banner material is ideal for:

- High-rise façades

- Construction fences

- Stadium exteriors

The airflow-permeable design reduces wind load while maintaining visual impact.

Choosing the Right Weight and Thickness

Material weight influences installation options, durability, and handling. Common weights range from 240gsm to 510gsm and beyond.

| Weight Range | Recommended Use | Material Behavior |

|---|---|---|

| 240–320gsm | Indoor signage, short-term promotions | Lightweight, easy handling |

| 340–440gsm | Mid-term outdoor use, event banners | Balanced durability and flexibility |

| 450–510gsm | Long-term outdoor advertising | Strong, thick, weather-resistant |

| Mesh materials (various gsm) | High-wind areas, building wraps | Airflow design, reduced stress |

Heavier materials improve durability but may require reinforced installation hardware.

Print Method Compatibility Considerations

PVC banner material must match your printing technology.

Solvent and Eco-Solvent Printing

Suitable for outdoor banners due to:

- High ink adhesion

- Long outdoor life

- Strong color stability

UV Printing

Ideal for:

- High-precision images

- Fast production cycles

- Applications requiring scratch resistance

Latex Printing

Preferred for:

- Indoor displays

- Odor-free advertising

- Smooth color reproduction

Selecting the correct banner surface ensures consistent results across technologies.

Installation Requirements and Material Optimization

Installation conditions influence material choice. Consider:

- Whether the banner will be hung, framed, or stretched

- Wind exposure

- Required finishing options such as grommets, pole pockets, or welded edges

Edge Reinforcement

Coated PVC banner material handles welding more effectively due to its thicker and stronger structure.

Curling Resistance

Materials with stable scrim structures reduce curling and deformation.

A well-matched material minimizes installation time and ensures long-term stability.

Environmental Considerations and Material Sustainability

Modern printing projects increasingly prioritize eco-friendly solutions. When selecting PVC banner material, evaluate:

- Availability of recyclable materials

- Low-odor coatings for indoor spaces

- Reduced-emission printing compatibility

Sustainable material choices help organizations align with environmental goals while maintaining print performance.

How to Evaluate Quality Before Purchasing

Reliable evaluation methods include:

- Checking surface uniformity and texture

- Testing tensile strength and tear resistance

- Inspecting coating thickness

- Verifying print test samples

- Ensuring proper opacity and light-blocking performance

These steps help confirm that the selected PVC banner material meets project requirements.

Recommended Selection Strategy for Different Projects

Below is a practical decision-making chart that aligns project types with material characteristics:

| Project Type | Best Material Choice | Key Reasons |

|---|---|---|

| Indoor advertising | Laminated PVC banner | Lightweight, smooth print quality |

| Outdoor long-term advertising | Coated PVC banner | Durability, UV resistance |

| Large building wraps | Mesh PVC banner | Wind-permeable structure |

| Event backdrops | Coated lightweight banner | Flexibility, high-quality printing |

| Retail promotions | Laminated or coated | Cost-effective and versatile |

Selecting the right category ensures efficient production and stable display performance.

Conclusion: A Strategic Approach to Selecting PVC Banner Material

Choosing the right PVC banner material requires balancing durability, print quality, installation conditions, environmental exposure, and budget. By understanding structural types, surface treatments, print technology compatibility, and project-based requirements, you can ensure long-lasting and high-impact results for any printing scenario.

Whether producing indoor signage, outdoor banner printing, event displays, or large-scale building wraps, the correct material selection ensures consistent performance, clarity, and reliable resistance to environmental challenges. Following the guidelines above will help maximize both visual effectiveness and operational efficiency across all types of display projects.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126