The outdoor advertising sector has undergone rapid changes driven by evolving installation environments, rising safety standards, and growing demand for large-scale visual communication. Among the wide range of materials used for outdoor advertising banners, two categories have maintained long-term prominence: mesh banner material and vinyl banner. Although both are essential components of modern visual marketing, they differ significantly in structure, performance, installation requirements, and application suitability.

Structural Characteristics: The Foundation of All Performance Differences

Material structure directly affects outdoor durability, visual quality, and overall reliability. Mesh banner material and vinyl banner represent two distinct structural categories that cater to different environmental conditions and technical expectations.

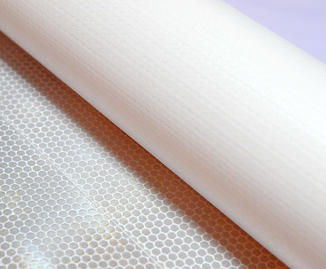

The Structural Nature of Mesh Banner Material

Mesh banner material is manufactured through the combination of a PVC coating and a perforated scrim base. The presence of evenly distributed micro-holes forms a semi-transparent, breathable structure designed for high-wind environments and large-scale applications.

Key structural attributes include:

- High air permeability: Holes allow wind to pass through, reducing pressure on installation points.

- Reduced weight: Ideal for oversized banners and elevated installations where load limits are strict.

- Light diffusion: Partial light transmission minimizes glare and creates a softer visual appearance.

- Surface stability: The mesh structure reduces material deformation when exposed to strong winds.

These characteristics make mesh banner material particularly suitable for scenarios where wind resistance and structural safety are key factors.

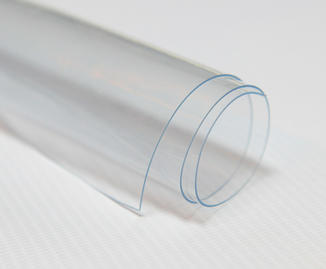

The Solid Structure of Vinyl Banner

Vinyl banner (often referred to as PVC banner) has a fully coated, non-perforated surface that provides a denser, smoother printing surface. This material remains a popular choice for projects requiring vivid colors and high-resolution images.

Core attributes include:

- Superior image clarity: The smooth surface supports high-precision large format printing.

- High tensile strength: The dense structure offers tear resistance for fixed installations.

- Versatile light control: Available in frontlit, backlit, and blockout variations.

- Broad application adaptability: Effective across multiple indoor and outdoor advertising scenarios.

Vinyl banner is widely recognized for its strong visual performance and consistent output quality.

Performance Comparison: Choosing Based on Application Requirements

The following table outlines the essential performance differences between mesh banner material and vinyl banner, offering a quick reference for selecting the appropriate material for various outdoor advertising projects.

Performance Comparison Table

| Category | Mesh Banner Material | Vinyl Banner |

|---|---|---|

| Structure | Perforated, breathable | Solid, dense surface |

| Wind resistance | Excellent; reduces wind load | Moderate; requires strong fixation |

| Weight | Light | Medium to heavy |

| Print quality | Good for long-distance viewing | High resolution for close-range visibility |

| Light transmission | Partial | Varies by frontlit/blockout type |

| Durability | Strong under stress | Stable under general weather conditions |

| Preferred environments | Construction sites, scaffolding, stadium exteriors, large fences | Retail advertising, street banners, event signage, commercial displays |

| Installation complexity | Easy; lower wind pressure | Requires stronger mounting points |

| Cost level | Medium | Medium to low (depending on weight and type) |

Outdoor Application Differences: Wind Load and Installation Drive Material Choice

Wind Load Management as the Critical Distinction

From construction sites to waterfront installations, wind pressure is one of the influential environmental factors affecting banner performance.

-

Mesh banner material is designed for ventilation. Its perforated structure drastically reduces wind resistance, making it safer in elevated or exposed locations such as building façades, scaffolding covers, long fences, and large event barricades.

-

Vinyl banner, on the other hand, acts as a solid surface. In high-wind environments, it can accumulate significant force, placing strain on both the material and installation hardware. While still suitable for general outdoor use, it requires more robust reinforcement such as additional grommets, tension systems, or structural support.

Visual Quality Requirements Shape Material Selection

When the primary objective is high-detail imagery—typical of retail promotions, brand visuals, or close-up viewing—vinyl banner remains the choice. Its uninterrupted surface allows for crisp text, precise graphics, and intense color saturation.

Mesh banner material, though capable of producing attractive prints, may show a subtle texture upon close inspection due to its holes. However, for distant viewing or oversized applications such as stadium wraps, building covers, or festival barricades, this effect is negligible.

Application Scenarios: How Each Material Fits Real-World Usage Needs

Mesh Banner Material: Optimized for Large-Scale and High-Wind Installations

Mesh banner material is widely used in:

- Construction and scaffolding wraps: Provides dual functionality—visual coverage and reduced wind load.

- Event and festival perimeter fencing: Offers branding opportunities without compromising structural safety.

- Stadium exteriors and sports arena displays: Suitable for gigantic graphics viewed from long distances.

- Coastal or high-wind zones: Maintains stability where traditional banners may fail.

Its combination of safety and durability makes it one of the in-demand outdoor advertising banners for large and exposed environments.

Vinyl Banner: Prioritizing High Visual Impact

Vinyl banner excels in:

- Retail storefront graphics: High-resolution prints attract consumer attention.

- City street banners and pole signs: Offers bold color and superb clarity.

- Short-term promotions and event signage: Easy to produce, versatile to install.

- Long-term fixed displays: Excellent weather resistance in moderate wind environments.

The material’s visual precision makes it the preferred choice when clarity and color vibrancy are primary goals.

Production and Processing Differences: How Material Structure Shapes Workflow

Production Characteristics of Mesh Banner Material

Because mesh banner material contains micro-holes, printing and finishing require tailored methods:

- Ink deposition control: Adjusted ink droplets prevent oversaturation or leakage.

- Heat welding or reinforced edge finishing: Stabilizes the banner for outdoor stress.

- Specialized installation accessories: Such as reinforced grommets, mesh-compatible ties, or mounting nets.

Production facilities typically rely on specific workflows to ensure print uniformity across the perforated surface.

Production Requirements for Vinyl Banner

Vinyl banner’s solid surface simplifies high-resolution printing but demands attention in finishing processes:

- Balanced base scrim selection: Strength and weight must align with usage conditions.

- Choice of light-control structure: Frontlit for general visibility, blockout for double-sided printing, etc.

- Multiple processing methods: Including heat welding, seam reinforcement, rope insertion, and hemming.

- Broad installation compatibility: Suitable for frames, tension systems, poles, hooks, or simple rope mounting.

This flexibility contributes to vinyl banner’s dominance in commercial advertising.

Conclusion: Mesh and Vinyl Are Complementary Rather Than Competitive

A balanced assessment of both materials reveals that mesh banner material and vinyl banner are not substitutes for one another. Instead, each excels under specific conditions.

Use mesh banner material when:

- Wind resistance is essential

- The banner is extremely large

- Installation occurs at elevated or exposed sites

- Structural safety is a top priority

Use vinyl banner when:

- High-precision image quality is required

- Viewers are close to the banner

- Long-term visual clarity is needed

- The environment has low to moderate wind pressure

Strategically selecting between the two materials—or using both in different zones—can create safer, more efficient, and visually compelling outdoor advertising installations.

FAQ

1. Is mesh banner material suitable for all outdoor advertising environments?

Not always. It performs in high-wind or large-format scenarios. For detailed images or close-range viewing, vinyl banner remains the more appropriate choice.

2. Does the heavier weight of vinyl banner create installation challenges?

For very large banners, additional reinforcement may be necessary. However, proper grommets, tension systems, and edge welding typically resolve any structural concerns.

3. Will the perforated texture of mesh banner material affect image appearance?

Only at close range. For distant viewing, construction wraps, stadium banners, or oversized prints, the visual difference is minimal.

4. Can mesh and vinyl banners be used together in one project?

Yes. Many large installations combine mesh for upper windy areas and vinyl for lower sections requiring sharper detail.

5. Which material is more durable?

Both are designed for outdoor use. Mesh is more stable under wind pressure, while vinyl provides longevity in controlled wind environments.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126