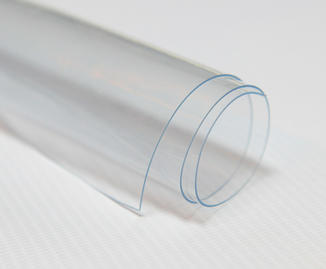

In the packaging material market, rigid pvc super clear stretch film is favored for its transparency. And this transparency is inseparable from advanced production technology. Especially in the key production link of extrusion blow molding, the precise control of parameters such as temperature, pressure, and blow-up ratio.

The cornerstone of uniform plasticization

Temperature is a key variable in the plasticization process of PVC resin, which runs through all stages of extrusion blow molding production. In the material transmission path from the fuselage, the neck to the head, the temperature must be set accurately in a gradient. When the PVC resin enters the extruder, the fuselage temperature must be maintained in a suitable range. At this temperature, the force between the resin molecular chains is weakened, and it begins to soften and gradually plasticizes. As the material advances to the neck and head, the temperature gradually increases to ensure that the resin can be fully plasticized. The appropriate extrusion temperature can make the PVC resin evenly distributed, just like kneading an irregular piece of clay into a uniform body. Once the temperature control is improper, the resin is not fully plasticized, and crystal points or bubbles will be generated. Crystal points are like tiny impurities in the film, which scatter light; bubbles change the medium for light propagation, causing disordered light refraction, both of which will seriously reduce the transparency of the stretch film.

Balance of material flow

In the process of extrusion blow molding, pressure plays an important role in ensuring the stable transportation and compaction of materials. From the screw pushing the material forward to the die head extrusion molding, the size and stability of the pressure directly affect the flow state of the material in the mold. Stable and appropriate pressure is like setting a precise "travel route" for the material, which promotes its uniform flow during the extrusion process and avoids local accumulation or uneven flow rate. If the pressure is too high, the material will be over-compressed in the mold, which may not only change the structure of the PVC molecular chain, but also cause stress concentration inside the film, affecting transparency; if the pressure is too low, the material cannot be fully compacted, and gaps will be formed inside the film, and diffuse reflection will occur when light passes through, which also reduces transparency. Pressure regulation needs to find a precise balance point based on factors such as resin characteristics and equipment parameters to ensure that the material is molded in the state.

Optimizer of molecular structure

The blowing ratio refers to the ratio of the transverse diameter of the film after blowing to the diameter of the tube blank before blowing. This parameter has a crucial impact on the molecular structure and transparency of the film. When the film is blown, the PVC molecular chains are forced to stretch and rearrange under the action of transverse and longitudinal tensile forces. A reasonable blowing ratio can make the molecular chains evenly oriented in two directions, forming a regular and orderly molecular structure, just like combing messy silk threads neatly. Under this uniform molecular structure, the refraction and scattering of light when passing through the film are significantly reduced, thereby greatly improving transparency. If the blowing ratio is too large, the film will be over-stretched in the transverse direction, resulting in excessive transverse orientation of the molecular chains, weakened longitudinal strength, and stress whitening may occur, reducing transparency; if the blowing ratio is too small, the molecular chains cannot be fully stretched, the molecular structure is loose, and the transparency is also affected. According to production needs and resin properties, controlling the blowing ratio within an appropriate range is the key to optimizing the molecular structure of the film and improving transparency.

System engineering of production process

Temperature, pressure and blowing ratio do not act independently, but are interrelated and synergistic. Temperature affects the plasticization degree and fluidity of the resin, which in turn affects the pressure distribution and the blowing effect; changes in pressure will change the flow rate and plasticization state of the material, and together with the temperature, determine the final form of the resin; the blowing ratio further optimizes the molecular structure and appearance performance of the film on the basis of temperature and pressure shaping. Only when these three parameters are accurately matched and form an organic synergistic system can a rigid PVC super clear stretch film with high transparency be produced. From resin plasticization to film molding, the fine-tuning of each parameter requires comprehensive consideration of other factors.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126