PVC tarpaulin has become a vital material in multiple industries due to its versatility, durability, and protective properties. Widely used in construction, transportation, agriculture, and outdoor activities, PVC tarpaulin serves as a robust solution for shielding goods, equipment, and structures from environmental elements.

Definition and Basic Overview

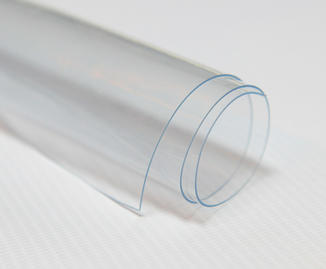

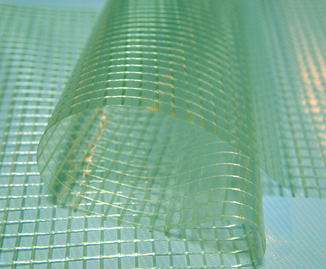

PVC tarpaulin, also known as polyvinyl chloride tarpaulin, is a flexible, waterproof material manufactured by coating or laminating PVC onto fabric such as polyester or canvas. The combination of PVC and high-strength fabric creates a material that is resistant to tearing, UV rays, and adverse weather conditions. PVC tarpaulin manufacturers have refined the production process to achieve materials that balance flexibility with toughness, making them suitable for both temporary and permanent applications.

The core appeal of PVC tarpaulin lies in its protective capabilities. Its waterproof nature prevents water penetration, while its reinforced structure ensures high tensile strength. This dual property makes it an indispensable material for outdoor applications and industrial use.

Durability and Waterproof Performance

One of the significant characteristics of PVC tarpaulin is its durability. Heavy-duty PVC tarpaulin can withstand prolonged exposure to harsh environmental conditions without significant degradation. The material is resistant to punctures, tears, and abrasions, providing reliable protection in demanding conditions such as construction sites or agricultural fields.

The waterproof nature of PVC tarpaulin is equally essential. The PVC coating creates an impermeable barrier that blocks rain, moisture, and other liquids. This feature makes it suitable for applications where water damage must be prevented, such as covering vehicles, machinery, and outdoor storage areas.

Common types of PVC tarpaulins:

| Type of PVC Tarpaulin | Surface Treatment | Material Composition | Key Features | Typical Applications |

|---|---|---|---|---|

| Frontlit PVC tarpaulin | Glossy or matte finish | PVC coated polyester | High visibility, good waterproofing | Outdoor advertising banners |

| Backlit PVC tarpaulin | Translucent finish | PVC laminated fabric | Light transmission, waterproof | Illuminated signage |

| Blockout PVC tarpaulin | Opaque, double-sided | PVC coated polyester | Full light blockage, durable | Large-format printing, stage covers |

| Heavy-duty PVC tarpaulin roll | Reinforced edges | Multi-layer PVC fabric | Tear-resistant, waterproof | Industrial covers, truck tarps |

| UV resistant PVC tarpaulin | UV-protected coating | PVC laminated canvas | Sunlight resistance, waterproof | Agriculture, outdoor storage |

Applications of PVC Tarpaulin

PVC tarpaulin manufacturers produce materials tailored for diverse applications. One primary area is construction, where PVC tarpaulin is used to cover building materials, scaffolding, and temporary structures. Its durability ensures that even under continuous exposure to rain and wind, the covered materials remain protected.

In the transportation sector, PVC tarpaulin is employed as truck covers, cargo wraps, and protective sheets. Heavy-duty PVC tarpaulin rolls are preferred due to their resistance to punctures and tears during transport. The waterproof feature prevents goods from being damaged by unexpected rainfall, making logistics operations more reliable.

Agriculture also benefits from PVC tarpaulin’s protective qualities. Transparent and UV-resistant PVC tarpaulin can be used as greenhouse coverings, shielding crops from harsh sunlight and precipitation. Farmers often rely on reinforced PVC tarpaulin sheets to protect equipment, hay, and fertilizers from weather-related damage.

Outdoor and recreational applications are another major use case. Waterproof PVC tarpaulin is widely used for tents, camping grounds, and temporary shelters. Its flexibility allows for easy handling, while its durability ensures prolonged use in challenging outdoor conditions.

Durability Testing and Standards

PVC tarpaulin manufacturers often adhere to specific testing standards to ensure product quality. These standards evaluate tensile strength, tear resistance, waterproof performance, and UV stability. Heavy-duty PVC tarpaulin typically exhibits high tensile strength, making it resistant to stretching under load.

The waterproofing properties of PVC tarpaulins can be tested using a water column measurement, which determines the amount of pressure the material can withstand before leaking. UV resistance is also crucial for outdoor applications, as prolonged sunlight can degrade the material. High-quality PVC tarpaulins are manufactured with UV-resistant additives to maintain their strength and appearance.

Typical performance indicators of PVC tarpaulin:

| Property | Measurement Method | Typical Value / Standard | Importance |

|---|---|---|---|

| Tensile Strength | ASTM D5035 | 300–800 N/5 cm | Determines tear and load resistance |

| Waterproof Rating | Water column test | 1000–5000 mm | Ensures protection from water ingress |

| UV Resistance | ASTM G154 / EN 1297 | 200–500 hours | Prevents sun-related material aging |

| Tear Resistance | ASTM D4533 | 40–200 N | Indicates puncture resistance |

| Weight per Unit Area | GSM (grams/m²) | 250–1000 g/m² | Affects durability and handling |

Advantages of Using PVC Tarpaulin

Weather Resistance: PVC tarpaulin is resistant to rain, sunlight, and wind, making it suitable for outdoor applications.

Longevity: Heavy-duty PVC tarpaulin offers long service life without frequent replacement.

Versatility: Available in multiple types, surfaces, and thicknesses to meet diverse industrial and commercial needs.

Ease of Handling: Flexible and lightweight options allow for easy installation and removal.

Cost-Effectiveness: While durable and robust, PVC tarpaulin is a cost-efficient solution compared to other protective materials.

Choosing the Right PVC Tarpaulin

Selecting the appropriate PVC tarpaulin depends on the intended application. For instance, outdoor advertising banners benefit from frontlit or backlit PVC tarpaulin sheets, while industrial covers require heavy-duty, tear-resistant rolls. PVC tarpaulin manufacturers often provide customization options such as specific thickness, coating type, or reinforcement to meet client requirements.

Key factors to consider include:

Intended exposure to environmental conditions (sunlight, rain, wind)

Required strength and tear resistance

Desired flexibility for handling and installation

Additional features like UV or fire resistance

Conclusion

PVC tarpaulin is a versatile and essential material with unmatched durability and waterproof properties. Its applications span construction, transportation, agriculture, and outdoor activities, making it a staple in industries where protection from environmental elements is critical. Heavy-duty and UV-resistant options provide long-lasting performance, while a wide variety of types and customizations ensure that PVC tarpaulin meets specific user requirements.

PVC tarpaulin manufacturers continue to innovate, improving the material’s strength, flexibility, and protective capabilities. For industries and individuals seeking reliable, cost-effective solutions for covering and protecting goods, PVC tarpaulin remains an indispensable choice.

Through careful selection of type, coating, and reinforcement, users can fully leverage the durability and waterproof performance that makes PVC tarpaulin an industry-standard protective material.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126