Introduction to PVC Flex Banners

PVC flex banner has become one of the widely used materials in the advertising industry due to its versatility, durability, and cost-effectiveness. As a synthetic material made primarily from polyvinyl chloride (PVC), these banners are designed to withstand a wide range of environmental conditions, making them suitable for both indoor and outdoor applications. The unique material composition of PVC flex banners allows them to offer a balance of flexibility and strength, which is crucial for large-format displays and outdoor installations.

The core advantage of PVC flex banners lies in their adaptability. Unlike paper or fabric banners, PVC flex banners can maintain structural integrity under weather conditions while providing high-quality print reproduction. This makes them particularly valuable for long-term promotional campaigns and large-scale advertising initiatives.

Types of PVC Flex Banners

PVC flex banners can be categorized based on surface properties and material finishes. The surface type determines light transmission, visibility, and application suitability, while the material finish affects aesthetic appeal and durability. Understanding these distinctions is essential for choosing the right banner for specific advertising needs.

Based on Surface

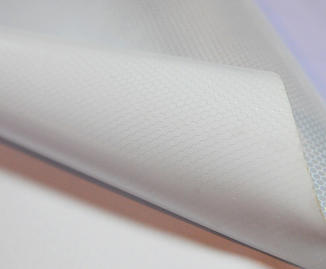

Frontlit Banners

Frontlit banners are designed to be illuminated from the front. The surface is optimized to display vibrant colors under direct lighting, making them ideal for outdoor signage and billboards. The material provides a balance between flexibility and print clarity.

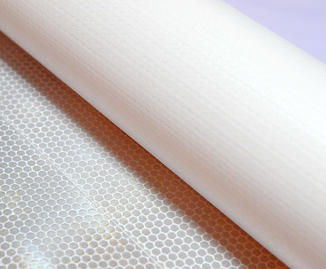

Backlit Banners

Backlit banners allow light to pass through from behind, enhancing visual appeal in illuminated settings. These banners are commonly used for displays requiring high visibility during night time, such as retail lightboxes or building facades.

Blockout Banners

Blockout banners feature an opaque layer that prevents light from passing through. This ensures that graphics and text remain clearly visible even in high-light environments, preventing visual interference from overlapping light sources.

| Banner Type | Light Transmission | Typical Use Case | Durability Level |

|---|---|---|---|

| Frontlit | Low | Billboards, outdoor signage | High |

| Backlit | High | Lightboxes, retail displays | Medium |

| Blockout | None | Outdoor and double-sided banners | Very High |

Based on Material

Glossy PVC Flex Banner

Glossy PVC flex banners provide a reflective surface that enhances color vibrancy and visual impact. They are suitable for applications where attention-grabbing effects are required, such as trade show displays and promotional signage.

Matte PVC Flex Banner

Matte PVC flex banners offer a non-reflective finish, reducing glare under strong light conditions. This makes them suitable for large-format outdoor applications or areas with varying lighting, ensuring consistent visibility and readability.

Applications of PVC Flex Banners

PVC flex banners are versatile in their applications, ranging from outdoor billboards to indoor promotional displays. Their performance and durability largely depend on material properties such as thickness, flexibility, and weather resistance.

Outdoor Advertising

Outdoor advertising demands banners that can withstand environmental stress, such as UV exposure, rain, and wind. PVC flex banners are commonly used for:

Billboards: Large-scale banners that need durability and high-quality print clarity.

Signage: Directional or informational signs that require weather resistance.

Building Wraps: Large facade banners that cover structures for promotional purposes.

| Application | Material Requirement | Key Feature |

|---|---|---|

| Billboards | Thick PVC flex banner | UV resistance, tear strength |

| Signage | Medium-thick PVC | Weatherproof, high print quality |

| Building Wraps | Heavy-duty PVC | Flexibility, wind resistance |

Indoor Advertising

For indoor applications, factors such as visual appeal, ease of installation, and surface finish play a critical role. PVC flex banners are extensively used for:

Trade Show Displays: Portable and reusable banners that provide vibrant visuals.

Retail Promotions: Eye-catching displays for product launches or seasonal campaigns.

Point-of-Sale Displays: Compact banners for in-store promotion with high print fidelity.

Event Signage

PVC flex banners are frequently used for events due to their versatility and ability to display large graphics clearly:

Concerts and Festivals: Backlit or blockout banners for stage and venue branding.

Sports Events: Durable banners for stadiums or outdoor venues.

Conferences and Seminars: Indoor banners for wayfinding and promotional content.

Printing Techniques for PVC Flex Banners

The choice of printing method significantly impacts the final appearance, durability, and cost of PVC flex banners.

Solvent Printing

Solvent printing involves the use of solvent-based inks that penetrate the PVC surface.

Advantages: Strong adhesion, suitable for outdoor applications, vibrant color output.

Disadvantages: Slower drying time, environmental concerns due to volatile organic compounds (VOCs).

Eco-Solvent Printing

Eco-solvent inks offer reduced VOC emissions while maintaining print quality.

Advantages: Environmentally friendly, compatible with multiple PVC surfaces, good color reproduction.

Disadvantages: Slightly lower durability compared to traditional solvent inks.

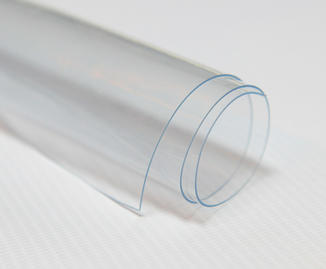

UV Printing

UV printing uses ultraviolet light to cure inks directly on the PVC surface.

Advantages: Immediate drying, resolution, suitable for intricate designs.

Disadvantages: Higher equipment cost, less flexibility in ink penetration.

Latex Printing

Latex printing uses water-based inks that are cured using heat.

Advantages: Eco-friendly, flexible, scratch-resistant.

Disadvantages: Requires specific curing systems, slightly limited outdoor longevity.

| Printing Method | Key Advantage | Limitations | Typical Use Case |

|---|---|---|---|

| Solvent | Strong outdoor durability | VOC emissions | Billboards, outdoor signage |

| Eco-Solvent | Reduced environmental impact | Slightly lower durability | Retail banners, indoor signage |

| UV | High-resolution graphics | High equipment cost | Trade shows, promotional materials |

| Latex | Flexibility and scratch resistance | Specialized curing system | Indoor and outdoor displays |

How to Choose the Right PVC Flex Banner

Choosing the correct PVC flex banner requires careful consideration of several factors:

Consider the Application

Indoor vs. Outdoor Use: Outdoor banners require higher UV and water resistance.

Viewing Distance: Large-format banners may prioritize readability over detail.

Material Thickness

Weight and Durability: Heavier PVC provides better wind resistance and longevity, particularly for outdoor installations.

Printing Quality

Resolution and Color Accuracy: High-quality printing ensures brand messaging is clear and visually appealing.

Environmental Factors

UV Resistance: Prevents color fading under sunlight.

Water Resistance: Essential for outdoor durability.

Temperature Resistance: Maintains structural integrity under heat or cold.

Installation and Maintenance Tips

Proper installation and maintenance extend the lifespan of PVC flex banners significantly.

Proper Installation Techniques

Grommets and Hanging: Reinforced edges and grommets prevent tearing under stress.

Banner Stands: Portable stands support indoor applications and trade shows.

Cleaning and Storage

Best Practices for Longevity: Clean with mild detergent, avoid abrasive tools, and store rolled to prevent creases.

Environmental Considerations

While PVC flex banners are durable, environmental concerns must be addressed.

PVC Recycling: Certain facilities can recycle PVC banners, converting them into raw material for other products.

Eco-Friendly Alternatives: Some manufacturers explore biodegradable or PVC-free materials to reduce environmental impact.

Future Trends in PVC Flex Banners

Innovation in materials and sustainability is shaping the future of PVC flex banners.

Innovations in Materials: Development of lightweight, tear-resistant, and UV-stable PVC flex banners enhances versatility.

Sustainable Practices: Increased adoption of eco-solvent printing, recyclable PVC, and biodegradable alternatives reduces environmental footprint.

Conclusion

PVC flex banners remain a cornerstone in the advertising and promotional industry due to their versatility, durability, and adaptability. By understanding material properties, surface types, and printing techniques, advertisers can optimize the impact of their campaigns while ensuring longevity and environmental responsibility. Whether for outdoor billboards, indoor retail promotions, or large-scale event signage, PVC flex banners provide a practical, high-quality solution for diverse marketing needs.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126