The Core of Modern Advertising: Material Endurance

In the outdoor advertising sector, the flex banner remains a dominant medium due to its adaptability, affordability, and visual impact. Yet among all its technical attributes—printability, flexibility, color stability—the true determinant of market competitiveness is durability. The capacity of a flex banner to resist wind, rain, UV radiation, and temperature fluctuation directly defines its lifespan and performance reliability.

The demand for durable flex banner materials has grown alongside outdoor advertising expansion. In both metropolitan billboards and roadside installations, the expectation for long-term visibility without frequent replacement makes durability not merely a desirable feature but a fundamental requirement for cost efficiency and sustainability.

Composition and Structural Integrity of Durable Flex Banner

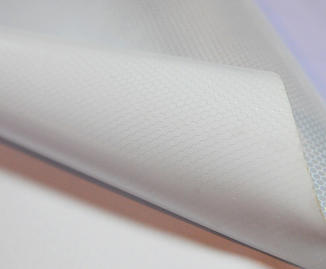

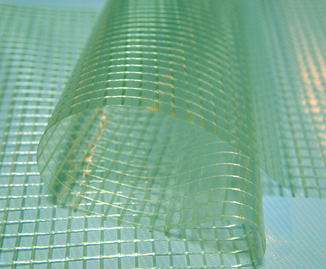

A high durability flex banner is primarily made from PVC layers combined with a polyester base fabric. The density and coating technique of these layers determine the banner’s tensile strength, flexibility, and weather resistance. Laminated and coated types of PVC flex banner vary in construction and performance, but both rely on the bond between the fabric base and PVC surface to withstand environmental stress.

The following table outlines common structural categories and their respective durability characteristics:

| Type of Flex Banner | Production Method | Surface Finish | Durability Level | Typical Application |

|---|---|---|---|---|

| Laminated flex banner | Heat lamination of PVC film and fabric | Gloss or matte | Medium | Indoor and short-term outdoor use |

| Coated flex banner | PVC coating directly fused with fabric | Smooth or textured | High | Long-term outdoor advertising |

| Frontlit flex banner | Light reflects on the printed surface | Semi-gloss | High | Billboard and wall display |

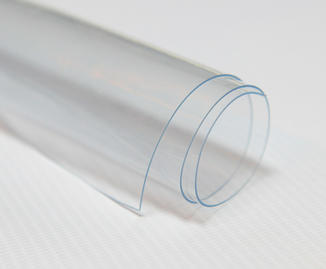

| Backlit flex banner | Light passes through material | Translucent | Very High | Lightbox or illuminated signage |

The enhanced tensile structure allows these materials to maintain their shape even under continuous tension from wind exposure. The internal weave density of polyester yarn also contributes to tear resistance and dimensional stability during prolonged use.

UV Resistance and Weather Adaptability

For outdoor advertising, ultraviolet radiation is the main factor that accelerates surface aging and color fading. Modern printable flex banner materials integrate UV-resistant coatings that slow molecular degradation within the PVC layer. This ensures that color remains vivid and text legible, even after months of sunlight exposure.

Weather adaptability also defines the versatility of waterproof flex banner products. The combination of waterproof coatings and flexible polymer composition prevents moisture infiltration and cracking in low temperatures. Whether deployed in humid coastal zones or dry desert regions, the banner retains elasticity without deformation.

Such material endurance has positioned the outdoor advertising pvc flex banner as a sustainable solution, minimizing replacement frequency and waste generation—both essential for environmental and cost management considerations.

Production Advances Enhancing Durability

Recent innovations in flex banner roll manufacturing have focused on improving coating uniformity and bonding strength. Coated production methods create a single-layer fusion between the fabric and PVC, reducing delamination risks that often occur in laminated versions. The outcome is a high durability pvc flex banner with consistent thickness and surface tension.

In addition, digital printing compatibility has become an integral factor in product development. The durability of the printed image depends on ink adhesion and surface coating quality. High-grade printable flex banner surfaces provide micro-texture adhesion points for solvent, eco-solvent, and UV-curable inks, ensuring the graphics resist both mechanical abrasion and chemical fading.

These manufacturing refinements have extended product lifespan while maintaining high-definition print resolution, enabling banners to function effectively in long-term campaigns or semi-permanent installations.

Eco-Friendly Evolution of Durable Materials

While durability increases banner longevity, modern market trends also prioritize environmental performance. The shift toward eco-friendly flex banner materials has introduced recyclable and low-emission PVC formulations. These solutions maintain high weather resistance and mechanical strength while reducing harmful plasticizers and volatile compounds.

Recyclable flex banner materials contribute to a circular production model, where used banners can be reprocessed into industrial raw materials rather than being discarded. This dual focus on durability and environmental safety positions the product as a viable component in sustainable advertising strategies.

In the table below, the evolving material standards for eco-friendly flex banners are summarized:

| Material Type | Environmental Feature | Durability Impact | Typical Use |

|---|---|---|---|

| Standard PVC | Conventional plasticizer content | High | General outdoor signage |

| Low-emission PVC | Reduced VOC emission | High | Indoor and semi-outdoor printing |

| Recyclable PVC | Recoverable after use | High | Long-term billboard applications |

| Non-PVC substrate | Fully recyclable | Medium | Short-term promotional displays |

Application and Market Relevance

Durable pvc flex banner rolls are now applied across a broad range of environments—from highway billboards to construction site fences and trade show backdrops. Their mechanical resilience reduces the risk of tearing during installation or in high wind conditions. For urban advertising, where maintenance access is limited, the reliability of the flex banner ensures uninterrupted visual communication.

In retail and event decoration, the matte finish flex banner variant offers a non-reflective surface ideal for indoor visibility under artificial lighting. For illuminated signage, the translucent backlit flex banner delivers consistent light diffusion and color intensity, crucial for brand and message clarity during night display.

The market value of durability thus extends beyond physical resistance; it encompasses performance consistency, color stability, and ease of printing. The integration of these attributes forms the foundation of a professional-grade outdoor advertising pvc flex banner.

The Future Direction of Flex Banner Technology

As the global printing and signage industry shifts toward sustainability and digital customization, the next stage in flex banner development focuses on smarter material engineering. Future trends include:

Hybrid polymer composition enhancing UV stability without toxic additives.

Improved surface coatings compatible with water-based inks for eco-printing.

Lightweight flexible structures reducing transportation cost and installation complexity.

Extended lifespan designs supporting long-term outdoor campaigns with minimal maintenance.

Durability will continue to evolve as a holistic standard encompassing strength, color fidelity, recyclability, and adaptability. With ongoing material innovation, the flex banner remains a crucial medium balancing practicality and environmental awareness in visual communication industries.

Conclusion

The significance of durability in flex banner manufacturing extends far beyond the product’s ability to endure weather extremes. It defines the efficiency, sustainability, and overall value proposition of modern advertising materials. Through advanced coating technologies, UV-resistant treatments, and eco-friendly polymer engineering, the flex banner continues to adapt to both environmental challenges and aesthetic demands.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126