The Rise of Functional Mesh Banner Materials

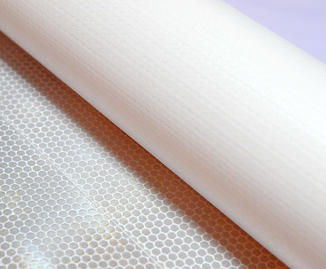

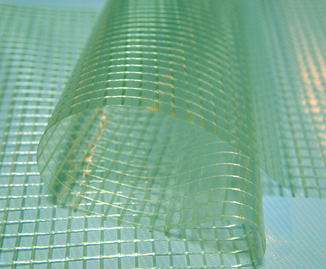

In the evolving outdoor advertising and architectural decoration industries, banner materials have shifted from traditional solid PVC films to mesh-based composites. Among these, the PVC liner mesh banner material roll has gained significant attention due to its balance between visual performance and structural adaptability. One of the distinctive technological advantages that distinguishes this material from conventional banner fabrics is its high air permeability.

Air permeability plays a crucial role in determining how a banner performs in outdoor environments—especially in high-wind regions, building wraps, or large-format advertising installations. Instead of focusing on durability or strength, this characteristic directly impacts installation stability, print quality, and the overall safety of large-scale displays.

Understanding Air Permeability in PVC Liner Mesh Banner Material Roll

Air permeability refers to the controlled flow of air through the micro-perforated surface of the mesh banner material. This design innovation minimizes wind resistance while preserving sufficient print surface for clear image rendering.

The material’s structure combines a flexible PVC coating with a high-strength polyester liner mesh, forming a stable yet breathable composite. Unlike solid PVC banner rolls, the mesh variant allows air to circulate freely, reducing drag forces that commonly cause banner deformation or tearing.

| Structural Feature | Description | Function in Air Permeability |

|---|---|---|

| Micro-perforated PVC surface | Uniformly distributed air holes | Reduces wind pressure load |

| Reinforced liner mesh | Polyester base grid | Maintains tensile strength under airflow |

| PVC coating layer | Flexible surface film | Ensures print adhesion and water resistance |

| Cross-weave pattern | Balanced warp and weft tension | Prevents tearing during wind exposure |

Air Permeability and Its Role in Outdoor Stability

Traditional full-surface PVC banners tend to act like sails when exposed to wind, generating significant pressure on mounting structures. The air-permeable nature of the mesh banner roll alleviates this issue by allowing wind to pass through the banner body.

For large-format applications, the impact of wind load reduction is substantial. Lower pressure results in less strain on mounting hardware, prolonging installation integrity without requiring additional reinforcement materials.

From an engineering standpoint, the uniform airflow distribution also prevents localized stress points. This not only enhances structural safety but ensures that visual elements such as printed logos or advertisements remain undistorted, even in challenging weather conditions.

The Impact on Visual Performance

One of the misconceptions about air-permeable materials is the assumption that perforation reduces print clarity. In the case of PVC liner mesh banner material roll, advanced coating and liner integration ensure that the printed graphics retain high definition.

Through controlled surface micro-patterns, the material allows ink to adhere evenly, avoiding color fading or inconsistency. This ensures that large outdoor graphics remain visually appealing under various lighting and environmental conditions.

Moreover, the mesh design minimizes glare and reflection, a benefit for banners displayed under direct sunlight. The controlled air and light transmission through the material’s structure creates a softer, more natural visual appearance compared to reflective solid PVC films.

Advantages for Installation and Transportation

Beyond its visual and structural benefits, air permeability directly influences logistics and installation efficiency. The lightweight design of the mesh banner material reduces overall transport volume and handling costs.

Installers benefit from its flexibility, as the roll can be easily adjusted, trimmed, and tensioned without compromising surface integrity. This adaptability has made it a preferred choice among mesh banner material suppliers catering to event organizers, construction projects, and urban advertising planners.

| Advantage | Description | Result |

|---|---|---|

| Lightweight roll format | Reduced material density | Easier handling and shipping |

| Flexible liner composition | Simple cutting and shaping | Faster on-site installation |

| Breathable structure | Minimizes wind stress | Fewer installation reinforcements required |

| UV and solvent print compatibility | Supports multiple print technologies | Broad application range |

Environmental and Design Implications

Air permeability contributes not only to mechanical performance but also to environmental adaptability. By allowing air to pass through rather than resist it, the material reduces the likelihood of structural failure and the need for excessive reinforcement materials, thereby minimizing waste during production and replacement cycles.

In architectural design, breathable mesh banners can serve dual purposes—functioning as both communication tools and temporary shading or facade components. The controlled permeability enhances airflow in building wraps, reducing heat accumulation and contributing to more sustainable temporary structures.

As global demand for lightweight, multifunctional banner materials increases, PVC liner mesh banner material roll represents a balance between technical innovation and environmental practicality.

Market Relevance and Industry Outlook

The global shift toward more flexible advertising and construction materials has led to rapid growth in demand for air-permeable solutions. Mesh banner material suppliers are focusing on optimizing airflow characteristics while maintaining print quality and tensile consistency.

The rising popularity of outdoor digital printing, coupled with stricter safety standards for temporary structures, positions the PVC liner mesh banner material roll as a strategic choice for various industries, including event management, construction, and commercial advertising.

As print technologies advance, the compatibility of the mesh banner material with eco-solvent, UV, and latex inks ensures its long-term market relevance. Additionally, its adaptability to both indoor and outdoor applications—such as building wraps, stage backdrops, or truck side curtains—broadens its potential usage scope.

Technical Comparison: Air Permeable vs. Solid PVC Banners

| Property | PVC Liner Mesh Banner Material Roll | Traditional Solid PVC Banner |

|---|---|---|

| Air Permeability | High – allows air flow through perforations | None – full wind resistance |

| Wind Load Resistance | Excellent – minimizes pressure | Poor – prone to tearing |

| Print Clarity | High – controlled surface perforation | Very high but reflective |

| Weight | Light to medium | Heavy |

| Installation | Simple – reduced reinforcement needs | Requires strong support frames |

| Application Areas | Building wraps, fences, event banners | Indoor displays, billboards |

This comparison highlights that while both materials serve advertising purposes, air-permeable mesh banners achieve performance in large-scale and outdoor applications where wind management is critical.

Conclusion: Air Permeability as a Defining Innovation

The evolution of PVC liner mesh banner material roll represents a key milestone in outdoor display materials. Its air-permeable structure is not merely a design enhancement—it is an engineering solution that directly addresses wind load challenges, installation flexibility, and print visibility.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126