Introduction

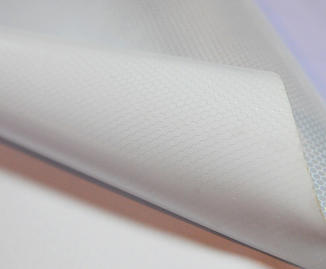

The mesh banner material stands out for its unique ability to combine durability, print clarity, and aerodynamic performance. Its defining feature—airflow design—directly influences how the banner interacts with wind and weather. This airflow-driven structure not only improves stability but also determines how effectively a banner can perform in open environments such as building wraps, stadiums, and construction sites.

The Science of Airflow in Mesh Banner Material

The foundation of mesh banner material lies in its perforated surface. These micro-holes allow controlled air passage, minimizing wind load and preventing banner flapping. This concept of aerodynamic permeability ensures banners maintain their visual and structural integrity.

| Structural Feature | Functional Impact | Outdoor Benefit |

|---|---|---|

| Micro perforations | Reduce air drag | Minimize wind pressure |

| PVC-coated polyester | Adds stability and weather resistance | Prevents deformation |

| Even airflow distribution | Maintains print clarity | Ensures long-term visibility |

| Reinforced seams | Strengthen edges | Prevents tearing |

Such engineering transforms a simple vinyl mesh banner into a high-performance advertising medium capable of withstanding outdoor stress while retaining vibrant color quality.

Composition and Material Optimization

A typical PVC mesh banner roll consists of three key components: polyester scrim, PVC coating, and perforated surface design. Each layer contributes to the overall airflow efficiency and durability.

| Component | Function | Airflow Influence |

|---|---|---|

| Polyester base | Provides structural strength | Supports tension control |

| PVC coating | Protects against UV, rain, and heat | Maintains flexibility |

| Perforated pattern | Controls air and light passage | Reduces turbulence |

| Ink receptive surface | Ensures high-resolution printing | Prevents color distortion |

Key Advantages of Airflow-Oriented Design

The aerodynamic configuration of mesh banner material delivers multiple advantages:

Wind Resistance – The perforations disperse wind load, enhancing banner stability in open-air settings.

Safety Enhancement – Reduced wind pressure lowers strain on installation structures.

Extended Lifespan – Controlled airflow reduces tension, minimizing edge fatigue and tearing.

Lightweight Handling – The breathable structure ensures easy installation and portability.

Visual Stability – Less vibration keeps printed graphics smooth and legible in windy conditions.

These benefits make outdoor mesh banner the preferred choice for large-scale advertising in exposed environments.

Printing Compatibility and Surface Technology

Airflow design does not compromise print quality. Instead, printable mesh banner material for inkjet printer is optimized to retain color saturation and definition across perforations. Its surface supports solvent, eco-solvent, and UV printing technologies.

Digital printing compatible mesh banner substrate maintains ink density even with airflow channels, producing vibrant images without compromising structural performance. This makes it ideal for large format mesh banner installations where visual impact must be preserved despite environmental challenges.

Environmental and Structural Sustainability

With sustainability becoming a global concern, eco-friendly mesh banner material with recyclable base is increasingly favored. These materials use non-toxic PVC compounds and recyclable polyester scrims, maintaining airflow efficiency while reducing environmental impact.

In construction and urban applications, such as mesh banner material for construction site fencing, airflow design also minimizes noise reflection and vibration—an often-overlooked environmental advantage.

Airflow Applications in Real-World Contexts

| Application | Function of Airflow | Product Type |

|---|---|---|

| Building wraps | Reduces wind drag | heavy duty PVC mesh banner material |

| Construction fencing | Prevents strain and improves visibility | mesh banner material roll for outdoor advertising |

| Stadium displays | Ensures stability and color retention | outdoor mesh banner fabric |

| Trade show backdrops | Maintains smoothness under indoor airflow | custom mesh banner material |

| Billboards | Enhances endurance against strong winds | large outdoor advertising mesh banner roll |

Each application leverages the same aerodynamic principle—controlled airflow delivering stability, safety, and clarity.

Future Development of Airflow Technology

Innovation in mesh banner material continues to evolve through advanced airflow modeling. Future materials will incorporate digital simulations using computational fluid dynamics (CFD) to refine hole geometry and air dispersion patterns.

Trends point toward high tensile strength mesh banner roll for outdoor use and breathable mesh banner material for windy area, combining lightweight performance with sustainable design. These advancements will further optimize the interaction between airflow efficiency and visual fidelity.

Conclusion

Airflow design defines the next generation of mesh banner material. By merging aerodynamic science with material engineering, it provides a foundation for banners that are safer, more stable, and environmentally responsible.

From perforated banner material to PVC mesh banner fabric, the integration of controlled airflow transforms each roll into a tool of visual efficiency—balancing the natural forces of wind with the demands of modern advertising.

English

English CN

CN ES

ES 86-573-88890126

86-573-88890126